Products

Water based environmently indoor and outdoor matt green acrylic floor paint

Acrylic Floor Paint

Front

Reverse

Technical Parameters

| Property | Non-Solvent based |

| Dry film thickness | 30mu/lay |

| Theoretical coverage | 0.2kg/㎡/layer ( 5㎡/kg) |

| Composition ratio | One-component |

| Using time after opening lid | <2 hours (25℃) |

| Touch drying time | 2 hours |

| Hard drying time | 12 hour (25℃) |

| Service life | >8 years |

| Paintcolors | Multi-color |

| Application way | Roller,trowel,rake |

| Self time | 1 year |

| State | Liquid |

| Storage | 5℃-25℃, cool, dry |

Application Guidelines

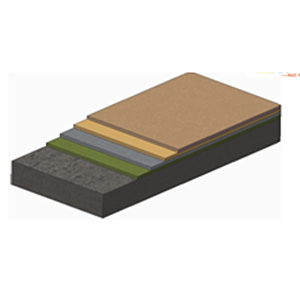

Pre-treated substrate

Primer

Middle coating

Top coating

Varnish (optionally)

| Application Scope | |

| Good performance floor paint for indoor and outdoor. Multifunctional and multipurpose suitable for floors in the industrial plants, school, hospitals, public places, parking lots and public buildings, tennis court, basketball court, public square etc. Especially suitable for outdoor floors. | |

| Package | |

| 20kg/barrel. | |

| Storage | |

| This product stored at above 0 ℃, well ventilation, shady and cool place. |

Application Instruction

Construction Conditions

Before painting, it is necessary to ensure that the polished surface is thoroughly cleaned to remove surface impurities and eliminate dirt. The ambient temperature should be between 15 and 35 degrees Celsius, the relative humidity should be less than 80%. Always use a hygrometer to check the wetness of the surface before doing a paint job to minimize flaking of the finish and prevent flaking between subsequent coats.

Application Step

Primer:

1. Mix primer A and B at a ratio of 1:1.

2. Roll and spread the primer mixture evenly on the floor.

3. Make sure the primer thickness is between 80 and 100 microns.

4. Wait for the primer to dry completely, usually 24 hours.

Middle Coating:

1. Mix middle coating A and B at a mixing ratio of 5:1.

2. Roll the middle coating mixture evenly and spread on the primer.

3. Make sure the thickness of the middle coating is between 250 and 300 microns.

4. Wait for the middle coating to dry completely, usually 24 hours.

Top Coating:

1. Apply the top coating to the floor directly(top coating is one-component), making sure the measured coating thickness is between 80 and 100 microns.

2. Wait for the top coating to dry completely, usually 24 hours.

Notes

1. Safety work at the construction site is very important. Always wear proper protective equipment, including tools for cleaning items, gloves to protect against paint stains, goggles, and a breathing mask.

2. When mixing paint, it must be mixed in strict accordance with the manufacturer's instructions, and the mixture should be fully stirred evenly.

3. When painting, ensure that the thickness of the coating is uniform, try to avoid lines and vertical lines, and keep the correct angle and level of the gluing knife or roller.

4. It is strictly forbidden to use fire sources or overheat the ground during construction. It is forbidden to use naked flames or high-temperature appliances, etc. If a ventilation system needs to be installed, preparations must be made before construction.

5. On construction sites or areas that require regular surface coating, such as parking lots or industrial areas, it is recommended to fully fix the previous coat before applying the next coat.

6. The drying time of each floor paint is different. Follow the manufacturer's instructions to determine the exact drying time of the coating.

7. Pay attention to the handling of flammable materials during the construction process, and do not pour floor paint materials into places where children can touch to avoid danger.

Conclusion

Using unique painting procedures and techniques, the construction process of acrylic floor paint is safe and effective. The application process provided here should be followed as recommended for best results. To ensure a safe and efficient construction environment, standardized cleaning equipment and painting tools are recommended.