Products

High quality environmently inside anti slip waterproof garage floor epoxy paint for concrete

Epoxy floor paint

Front

Reverse

Technical Parameters

| Property | Non-Solvent |

| Dry film thickness | 30-50mu/layer ( According to different matched coating requirement ) |

| Theoretical coverage(3MM) | primer is 0.15kg/㎡/layer,middle is 1.2kg/㎡/layer,top is 0.6kg/㎡/layer |

| Theoretical coverage(2MM) | primer is 0.15kg/㎡/layer,middle is 0.8kg/㎡/layer,top is 0.6kg/㎡/layer |

| Theoretical coverage(1MM) | primer is 0.15kg/㎡/layer,middle is 0.3kg/㎡/layer,top is 0.6kg/㎡/layer |

| primer resin(15KG):hardener(15KG) | 1:1 |

| middle coating resin(25KG):hardener(5KG) | 5:1 |

| self leveling top coating resin(25KG):hardener(5KG) | 5:1 |

| brush finished top coating resin(24KG):hardener(6KG) | 4:1 |

| Surface drying time | <8h ( 25°C ) |

| Touch drying time (hard) | >24h (25℃) |

| Service life | >10 years(3MM) / >8 years(2MM) / 5 years(1MM) |

| paint colors | Multi-color |

| Application way | Roller,trowel,rake |

| Storage | 5-25℃, cool, dry |

Application Guidelines

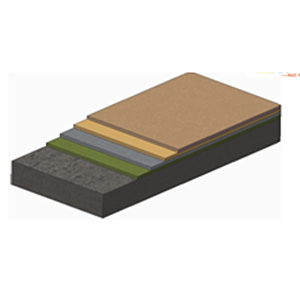

Pre-treated substrate

Primer

Middle coating

Top coating

Varnish (optionally)

| Application Scope | |

| Suitable for gymnasium, parking place, play ground, plaza, factory, school and other indoor floor. | |

| Package | |

| 25kg/barrel,24kg/barrel,15kg/barrel,5kg/barrel,6kg/barrel. | |

| Storage | |

| This product stored at above 0 ℃, well ventilation, shady and cool place. |

Application Instruction

Construction Conditions

Before construction, please ensure that the ground foundation is complete and meets relevant standards. The ground must be clean, level and dry. There must be no dust, peeled coating, grease or other impurities before painting. During construction, the temperature should be kept between 10°C and 35°C.

Application Step

Primer:

1. Mix epoxy floor primer part A and part B at a ratio of 1:1.

2. Stir fully to make components A and B fully mixed.

3. Apply the primer evenly to the ground with a roller, the primer coating should not be too thick or too thin.

4. Set the primer drying time to about 24 hours, and adjust the time appropriately according to the temperature and humidity conditions.

Middle Coating:

1. Mix components A and B of the epoxy floor middle coating in a ratio of 5:1, and stir well to fully mix.

2. Use a roller to evenly apply the middle coating to the ground, and the middle coating should not be too thick or too thin.

3. Set the drying time of the middle coating to about 48 hours, and adjust the time appropriately according to the temperature and humidity conditions.

Top Coating:

1. Mix components A and B of the epoxy floor top paint at a ratio of 4:1, and stir well to fully mix.

2. Use a roller to evenly apply the top coating to the ground, and the top coating should not be too thick or too thin.

3. The drying time of the top coating is set to about 48 hours, and the time should be adjusted appropriately according to the temperature and humidity conditions.

Notes

1. Breathable breathing masks, gloves and other related protective equipment must be worn during the construction process.

2. The best construction temperature of epoxy floor paint is 10℃-35℃. Too low or too high temperature will affect the curing of epoxy floor paint.

3. Before construction, the epoxy floor paint should be stirred evenly, and the proportion of components A and B should be accurately measured.

4. Before construction, the air humidity should be controlled below 85% to avoid adhesion or contamination

5. After the construction of epoxy floor paint is completed, the environment should be kept ventilated and dry.

Conclusion

The construction of epoxy floor paint requires careful implementation. Not only do you need to follow the construction steps, but you also need to pay attention to pretreatment and precautions. We hope this article can give you a more comprehensive understanding of the construction of epoxy floor paint, so as to help you achieve your desired effect with half the effort.