Products

High Performance and long service life steel structure fluorocarbon paint

Fluorocarbon Paint

Front

Reverse

Technical Parameters

| Property | Solvent based ( Oil based ) |

| Dry film thickness | 25mu/layer |

| Theoretical coverage | 0.2kg/㎡/layer |

| Mixed using time | <0.5h ( 25°C ) |

| Drying time (touch) | <2h ( 25°C ) |

| Drying time (hard) | >24h ( 25°C ) |

| Flexibility (mm) | 1 |

| Resistance to contamination (reflectance reduction rate,%) | < 5 |

| Scouring resistance (times) | > 1000 |

| Water Resistance (200h) | No blistering, no shedding |

| Salt spray resistance (1000h) | No blistering, no shedding |

| Corrosion Resistance: (10% sulfuric acid, hydrochloric acid)30 days | No change in appearance |

| Solvent Resistance: (benzene, volatile oil) for 10days | No change in appearance |

| Oil Resistance: (70 # gasoline) for 30 days | No change in appearance |

| Corrosion Resistance: (10% sodium hydroxide) for 30 days | No change in appearance |

| Service life | >15 years |

| Paint colors | Multi-colors |

| Application way | Roller, spray or brush |

| Storage | 5-25℃, cool, dry |

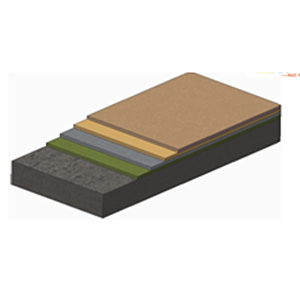

Application Guidelines

Pre-treated substrate

Primer

Middle coating

Top coating

Varnish (optionally)

| Application Scope | |

| Suitable for metal structure, concrete construction, brick surface, asbestos cement, and other solid surface decoration and protection. | |

| Package | |

| 20kg/barrel, 6kg/barrel. | |

| Storage | |

| This product stored at above 0 ℃, well ventilation, shady and cool place. |

Application Instruction

Surface preparation

he surface should be polished, repaired, dust collected according to the site basic surface condition; Correct substrate preparation is critical for optimum performance. Surface should be sound, clean, dry and free from loose particles, oil, grease, and other contaminants.

Application Step

luorocarbon special primer coating:

1) Mix ( A )Primer coating, ( B ) curinge agent and ( C ) thinner in a barrel according to ratio by weight;

2) Fully mix and stir in 4-5 min until without equal bubbles, ensure paint be fully stirred. The main purpose of this primer is to reach the anti-water,and seal the substrate completely and avoid air-bubbles in the body coating;

3) The reference consumption is 0.15kg/m2. Rolling, brush or spray the primer evenly (as the attached picture show) by 1 time;

4) Wait after 24 hours, the next application step to coat the fluorocarbon top coating;

5) After 24 hours, according to the site condition, polishing can be done, this is optionally;

6) Inspection: ensure the paint film is evenly with uniform color, without hollowing.

Fluorocarbon top coating:

1) Mix ( A ) fluorocarbon paint, ( B ) curing agent and ( C ) thinner in a barrel according to ratio by weight;

2) Fully mix and stir in 4-5 min until without equal bubbles, ensure paint be fully stirred;

3) The reference consumption is 0.25kg/m2. Rolling, brush or spray the top coating evenly (as the attached picture show) by 1 time;

4) Inspection: ensure the paint film is evenly with uniform color, without hollowing.

Notes:

1) The mixing paint should be used within 20 minutes;

2) Maintain 1 week, can be used when paint is solid absolutely;

3) Film protection: keep away from stepping on, rain, exposing to sunlight and scratching until the film is fully dried and solidified.